In today’s mechanically advanced world various types of milling machines are used to make different types of products from various types of materials.

Due to technological developments during the last few years, CNC milling machines are more in use as the computer network attached to them makes them more efficient.

But finding the best CNC milling machine may not be easier for you as many companies are introducing various types of CNC milling machines in the market.

Some of the CNC milling machines reviewed in this write-up can help you in choosing the best one for you.

What Is The Best CNC Milling Machine?

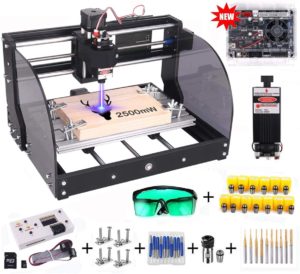

1. PVC Milling Engraving Machine by Genmitsu

This FCC/UL/CE approved CNC milling machine can ensure safety while working with a laser module for a long time due to its heavy-duty and strong structure.

It has been designed to ensure uninterrupted communication between the custom software and the hardware of the integrated mainboard.

Open-source high-performance software, GRBL, run on Arduino can control the movement of this machine more efficiently.

This best CNC milling machine is versatile as it can be used to cut various types of materials including soft aluminum, plastics, acrylics, woods, PCBs, and PVCs. It can be assembled easily with the help of the instructions provided in the package.

2. Yofuly PVC Milling Engraving Machine

The control board of this CNC milling machine can ensure its protection from short circuits with the help of the fixed heat sink, integrated drive chip, sturdy case, and external fan provided with it.

It includes an offline controller to operate this machine even without using a computer as you can use an SD card writer to write your instructions and control the machine accordingly.

It can engrave precisely for a long time due to its high power laser engraving capability. It can be controlled with the help of GRBL software used in it.

You can use this engraving machine for engraving on various types of materials like plastic, wood, PCB CCL, acrylic, soft metals, and paper, etc.

3. MCWDOIT CNC 3018 Pro GRBL Control Mini CNC Machine

The control board of this milling machine can extend its life by protecting it from short circuits with the help of an integrated driver chip, external fan, strong case, and fixed heat sink provided in it.

It is backed by the warranty for 12 months. You can use its assembled core components to install it easily in not more than 20 minutes.

It can be used by professional engravers as well as beginners as it can be operated with or without using a computer. You can write instructions on its SD card by using NC files or directory of G-code files.

It can carve on a variety of materials including acrylic, plastic wood, soft metals like aluminum and copper as well as PCB CCL, etc.

4. MYSWEETY 3 Axis Pcb Milling Machine

This upgraded version of its previous model works of GRBL software backed by a variety of Windows operating systems. This software allows you to use it without connecting to your computer as well as without downloading files.

You can download its software and user manual to use it easily for engraving on various types of materials like wood, plastic, PVC, acrylic, and PCB, etc. It can be assembled easily by hand as some of its core components come in the pre-assembled form.

Some of the important features of this entry-level CNC milling machine include small size, plastic body, us/b interface, lightweight, and control system of GRBL.

5. SZCY LLC DIY MINI CNC Engraving Machine

SZCY LLC has introduced this CNC milling machine as the upgraded version of its previous milling machine. They have made its assembling very easy as you need not position all of its components accurately. You can download it’s manual and software to assemble it easily.

They have used GRBL software to reduce the cost and improve the performance of this machine. This software helps in controlling the speed and movements of this machine to improve its performance.

It can be used to engrave on various types of materials including soft metals like aluminum, plastics, acrylics, woods, PCBs and PVCs, etc. this entry-level machine can allow you to learn how to care and inscribe by using lasers.

6. CENOZ 3 Axis PCB PVC Milling Engraving Machine

They have upgraded this best CNC milling machine according to the requirements of their customers by using GRBL controlled 3 axis system to make it more powerful and precise with the help of fixed heat sink, integrated driver chip, strongly built, and external fan.

You can start using this machine within less than 20 minutes after taking it out of the box as it can be assembled and positioned easily.

Its 3-axis control board of GRBL allows you to engrave on soft aluminum, plastics, acrylics, PVC, woods, and PCBs easily. You can control this machine, manually, offline as well as through your computer.

7. DIY Mini CNC Machine by SZCY LLC

This upgraded CNC milling machine has a laser head of 3000mW capacity which can be used easily after positioning it accurately as some of its components come in a pre-assembled state.

It has been designed to allow its hardware and software to perform seamlessly by communicating with each other easily.

The high-performance software GRBL used in it can help in controlling its movements and speed more effectively.

It can be used to cut all types of materials like soft aluminum, plastics, acrylics, woods, PCBs and PVCs, etc. you can download its software and user manual to assemble and use it easily.

8. SZCY LLC 5500mw Engraver CNC 3018 Pro Engraving Machine

It is the latest mailing machine introduced by SZCY LLC which can be used by professional engravers for milling and cutting various types of materials with its laser module.

In order to improve the accuracy of this machine, they have reduced its assembly and improved its stability by raising its height by 4cm.

They have extended their life by protecting it from the damages caused by a short circuit and providing an integrated chip of driver, external fan, fixed heat sink, and a strong case.

You can control its laser head and spindle manually. It can be used to carve various types of materials including acrylic, wood, plastic, soft metals like aluminum and copper as well as PCB.

Thus, the information provided in this write-up can help you to choose the best CNC milling machine for you as per your requirements.

FAQ:

CNC milling is also known for Computer numerical control milling. This process is allowing the computerized control and also rotates various cutting points to discard the material from the workpiece. This milling process can produce customized products.

This process is very much suitable for all kinds of materials such as metal, glass, plastic and wood. The best CNC milling machine can produce high-quality custom-designed products. So, as you can see, CNC milling is one of the top-most processes to make complex parts.

CNC milling is one kind of mechanical process including drilling and all other machinings methods. So, for better understanding, we need to take a deep dive into the process of CNC milling. You will get to know the multiple aspects of this particular process.

From this, you will understand the CNC milling process and its accuracy. Then, you can understand that the CNC milling process is one of the cost-effective alternatives.

What Is A CNC Milling Machine?

Now, it is time to know what CNC milling is. So, here you will get to know the meaning of it and clear some confusing points about this particular process. It is an automation process of machine tools.

It is set by the pre-programmed order through computer and control command as well. This process is opposite to the manually controlled operations by the help of levers and handwheels.

In the modern CNC system, the overall design and the manufacturing process are automated. So, as the mechanical parts. This process is a programmed code. It will represent instructions for the movements carried out by the machines.

So, this pre-programmed code defines and shows how to make and transform real objects from the virtual one.

So, as you can see, this machine interacts with the computer-based software and transform it into the coordinates. In this way, the machine will perform a high degree of performance with accuracy just like a robot.

Through the help of the different processes, the CNC machine can transform the raw materials into a final and finished product. But this depends on the machine and its type.

We all know that milling is the method including cutting and drilling. There is a huge difference between any type of drilling machine and a milling machine. The milling machine can cut in various angles and move in multiple axes as well.

How Many Types Of Cnc Milling Machines Are There?

It is an automatic machine tool. This machine is equipped with a computer control system. There are various types of CNC milling machines based on various methods.

1. According To Function:

According to the function of the machine parts, the CNC machine is available in five types. These are such as follows:

CNC Milling Machines: These machines are used to create holes, notches, pockets, shapes and grooves.

CNC Lathes: These are for making cylindrical parts and objects. This particular cutting tool can shape the working object or workpiece.

CNC Drilling Tool: It is used to create holes in the working object. This tool can easily find out the drilling position.

CNC Plasma Cutter: This particular tool has a plasma torch. It is useful to cut metals.

CNC Grinder: This machine can grind well to get the desired shape.

2. According To Motion:

According to motion, the CNC machine is divided into two systems. These are such as follows:

Point To The Point System: This type of machine includes boring, drilling and tapping machines.

Contouring System: This system can work continuously. This system includes lathes, routing and mill machines.

3. According To The Number Of Axis:

According to the division of the number of Axis, the CNC machines are available in 5 different groups. These are such as follows:

2 Axis Cnc Machine: This machine can give two Axis such as X and Z.

2.5 Axis Cnc Machine: This is not at all three dimensional. At first, the X and Y-Axis move to the position and after that, the third axis begins to work.

3 Axis Cnc Machine: This can move into three dimensions such as X, Y and Z.

4 Axis Cnc Machine: This is a 3 Axis machine with one extra rotation A Axis and B Axis.

5 Axis Cnc Machine: This is a 3 Axis machine with two extra rotations. This is an advanced type of CNC milling machine.

4. According To The Control Loop:

There are two different types of control loop systems such as follows:

Open-Loop System: The motor is one way. The process is very simple. It can also direct signals based on the requirements and purposes of the users. Closed-Loop System: It can correct the error. It also makes the correct acceleration and velocity.

What Are The Different Types Of Milling Process?

Milling is a process of removing materials with the use of rotary cutters. The CNC milling process is a computerized system that initiates the machine to perform automatically.

The BEST CNC MILLING MACHINE has several axes to offer precision and consistency with unmatched speed. Below mentioned are some of the most common types of CNC milling machines:

Vertical Milling:

In vertical milling, the tooling operation takes place in a vertical shape. A CNC machine consists of three axes. The tooling here moves vertically and the table moves front and back as well as side to side to get the desired shape.

These machines have several advantages and can be seen in many shops. They are cost-effective and are very easy to operate.

Horizontal Milling:

The horizontal milling machines serve the same purpose of removing materials from components but the tooling set here spins horizontally. Horizontal machines are more expensive when compared to the vertical drilling machine.

They are capable of offering more efficiency and better shape to components. They can be generally seen at large workshops due to the high prices.

Multi-Axis Machines:

In a multi-axis machine, each axis represents its movements. Machines that are beyond the three-axis are a perfect fit for CNC machines. The machines having beyond the three-axis can be very beneficial as the more complex machine setup.

They help to get complicated work done with ease. Multi-axis machine can remove materials from components as desired in any direction.

How Is The Cnc Machine Controlled?

A CNC machine is controlled through programs and inputs. The CNC machine is computerized which functions on the inputs that are fed to the system. When a CNC machine is activated, it first programs the designed cuts that are to be initiated.

This program is dictated to the tools and machinery to start the task. These machines function very similar to robots.

In a numerical control system, the placement of a tool is done through a part program. The part program is outlined by a series of inputs that are fed to the system to initiate operations.

The numerical control machine accepts inputs through punch cards. The programs are fed to the computer by programming the inputs for the best results.

The CNC machines can give more precise removal of materials as it is computerized. The chances of errors are very less and the system is not static.

The programmer can feed new inputs every time and get the desired output from the CNC machines. Pre-existing programs can be revamped by revised codes.

What Are The Advantages Of CNC Machine?

There are several advantages that CNC machines have over the manual machining system. CNC machines work on pre-programmed computer software having fewer chances of error and the product is precise. Below mentioned are some of the benefits of CNC machines.

Accuracy:

CNC machines offer accuracy and ensure consistency in supply that is why it is widely being used in many manufacturing centers worldwide. The process is more precise and can be repeated several times as per the requirements.

Consistency:

Manual machines are not consistent and entirely rely on the efforts put forward by workers. CNC machines are computerized and can manage the task very easily.

The precision is very accurate and the consistency remains the same irrespective of the load put on the machines. They perform it in peak hours as well as at normal production hours.

Increased Production:

A CNC machine is entirely computerized working automatically without the need for any supervision. As computers, control the machine there is no lag and the operating system does not require intervals. Hence, the production is increased by many folds using the CNC machines.

The quality and speed of manufacturing are better as the entire system is computerized and there are hardly any chances of errors.

Safety:

One of the biggest advantages of using a CNC machine is that they are safer than manual machines. What is even more exciting is that these machines work behind a door or in an enclosed area.

Workers working with CNC achiness are much safer as there are fewer chances of mishaps taking place at the workplace.

Cost-Effective:

CNC machines are very cost-effective when compared to manual machines. Manual machines require controllers and operators at every stop. The CNC machining process is automatic and does not require any supervision.

When the cost of operating employees is saved the machine, in the end, turns out to be very cost-effective. CNC machines require a lot fewer operators as the main task is handled automatically.

What Are The Disadvantages Of CNC Machines?

Several disadvantages come with this machine. Though the precision, consistency, and speed are outmatched to traditional machines yet there are several disadvantages of this machine. Below are mentioned some of the disadvantages of the CNC machines.

Cost:

The cost is one of the most prominent factors when it comes to CNC machines. These machines come with a hefty cost and require a large investment when compared to other traditional machines.

Gradually we are witnessing the rise of these machines that brings about the possibility of a reduction in the cost in years to come.

Loss Of Skill:

With the introduction of CNC machines, the skill of workers is lost. This is because whatever the skills that were required earlier are outdated due to the introduction of fully computerized machines.

These machines use very little workforce, which also confirms that many people would, not share the skills learned. Skill is valuable for workers, painters, artists, and many more professions. When computers and automation take over there is very little space for the skill to survive.

Unemployment:

What we have learned so far about CNC machines is that they are completely automated and run on programs fed to the system. The entire operation can be done with very little or no supervision at all. All this will decrease the demand for the workforce resulting in unemployment.

The need is now shifting to software engineers and mechanical engineers but the demand is very less. Overall it decreases the use of manpower resulting in fewer unemployment opportunities even for skilled workers worldwide.

FAQ Of Best CNC Milling Machine:

You should know that NC stands for numerical control and CNC stands for computer numerical control. The CNC milling machine is used for controlling the motion of the working object or the workpiece.

But in the case of the NC machine, various programs are fed into the punch cards. Apart from this, for operating the NC machine, you will need highly skilled and experienced workers. But less skilled operators can operate CNC milling machines.

The CNC milling process is cost-effective and beneficial also. But for this, you will have to purchase the best CNC milling machine.

The positioning accuracy considers the various movement of each coordinate Axis of the CNC machine. It is controlled through the numerical control device. The positioning accuracy will understand the motion accuracy of the CNC milling machine.

You can identify the positioning accuracy by simply reading errors. It is controlled by the numerical control system. So, testing the positing accuracy is very much necessary in this case.

The dynamic accuracy of the CNC milling machine depends on various factors such as stress. The greater stress factor will make it difficult to maintain the right accuracy of the machine.

But the machine builders should establish their machines correctly to achieve high accuracy for the particular application. There are some factors that you need to know:

-The construction of the machine

-The feedback system of the machine

-Calibration of machine tools

-Stable working circumstances