Are you amongst them who think that woodturning could be fun but never thought of pursuing it simply because you were afraid that it might end up getting too costly or maybe too complicated?

Well, we can relate to that, because turning is a dedicated division of woodworking and it requires its own set of tools as well as skill levels. That being said, it can sometimes feel like a different world altogether, even if you can figure out the way around the rest of the store.

The good part is, it is not that hard to start as you may have thought. This article is a quick guide on all you need to know about the best wood lathe tools and what all you would need to get you started.

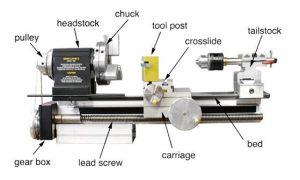

A LATHE:

Well no points for guessing, you will obviously need to get a lathe. The question here is which one? Besides an array of different brands available, the lathes also come in various sizes. So how would you decide if you need a mini, a midsize, or a monster lathe?

Your choice will be driven by the space you have at your shop or home, at the same time it will be about your pocket and the kind of woodwork you wish to engage yourself into.

It is completely your choice if you want to make pens or pizza cutter handles, or you might choose to make wooden bowls as well as table legs. With that being said, let us look at some wood lathe tools.

Turning Tools:

This is a removal process, you can create the product of your choice by removing excess material to create your final form. Like a sculptor, you need the correct tools to achieve the detaining you want.

There are two categories when it comes to the tools, the traditional tools, and the carbide-insert tools.

Traditional Tools:

Going by the name it is quite obvious that these tools have a respected and long history. For ages, craftsmen have used them to sculpt beautiful turnings.

The modern version of these tools is made of steel or to better the quality high-speed steel is used as it can tolerate high temperatures and can sharpen without dampening the hardness.

Gouges:

There are mainly of three types, let us know them:

Roughing gouge and the spindle gouge:

Mainly used to turn the spindles, which involve stocks longer than its width, and is placed in the lathe parallel to the lathes turning axis. Roughing gouges turn stock from the usual square shape to round shape, while the spindle gauge creates coves, even beads as well as other details.

In the spindle turning process, the lathe’s tool normally rests in a position close to the wood stock, so that it can support the tools that are near the cutting edge.

Whereas, bowl turning stock is normally placed in the lathe with the grain pointed perpendicular towards the turning axis. The important thing to understand is to use these tools for their defined purpose.

Skew chisels:

Equipped with angled cutting edges, they are used during the spindle turning to carve even shearing cuts and to make V-grooves as well as beads. There are various sizes available that are flat or oval, and even rounded shanks.

The angled edge used for cutting is straight but can be curved as well. Many of the craftsmen find that a decent amount of hands-on is required for perfecting the art to use the skew chisel.

Parting Tools:

These are the V-shaped tools and are intended to cut off a finished spindle that turns from the stock or blank. Normally, available in a rectangular shape as well as shafts that are diamond-shaped.

Some of them are also available in a thin version. Parting tools are normally used to cut grooves that mark cutting depths on the spindle turnings and can come with varied profiles.

Specialty Tools:

These tools include other types of tools like scrapers and different tools with cutter profiles intended to define bead details or shape dovetailed recesses that are required to secure the bottom of the bowl blanks.

So that is all it takes, all that you require to get you started with a lathe project, a few mentioned turning tools, the safety gear, and of course the wood. Happy crafting!